Industry: Manufacturing

Title: Embedded Systems Training Transforms Mechanical Engineering Team

Overview Box:

- Client: Manufacturing Equipment Supplier, Sweden

- Industry: Industrial Manufacturing / Automation

- Service: Training & Development

- Duration: 6 weeks intensive program

- Participants: 12 mechanical engineers

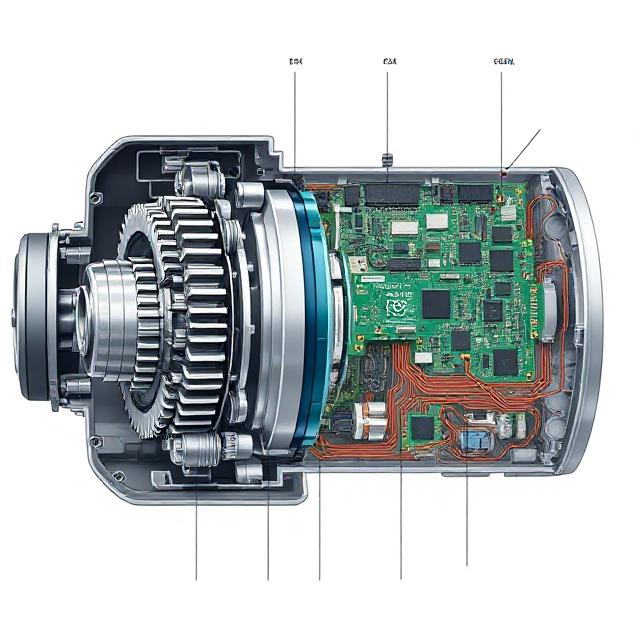

Challenge: A manufacturing equipment supplier was transitioning to increasingly software-driven products. Their mechanical engineers – highly skilled in mechanics, hydraulics, and pneumatics – needed to understand embedded systems to:

- Collaborate effectively with software engineers

- Debug issues in the field

- Design products considering software/hardware integration

- Reduce dependency on external embedded contractors

Previous training attempts failed because:

- Too theoretical, not practical enough

- No connection to company’s actual products

- Engineers felt intimidated and lost interest

Hisland’s Approach: We designed a custom “Embedded Systems for Mechanical Engineers” program specifically for this client:

Program Structure:

- Duration: 6 weeks

- Format: 2 evening sessions per week (3 hours each) + weekend hands-on labs

- Approach: 60% practical, 40% theory

- Projects: Using actual company hardware and products

Curriculum:

- Week 1-2: Embedded systems fundamentals, microcontroller basics

- Week 3-4: Sensor integration, CAN bus communication, real-world protocols

- Week 5-6: Real project work on company equipment, troubleshooting techniques

Teaching Methods:

- Live coding demonstrations

- Pair programming exercises

- Debugging real equipment failures

- Guest instructors from leading embedded companies

- Peer learning and knowledge sharing

Solution Delivered: ✓ 12 engineers completed intensive 6-week program

✓ 3 real projects completed using actual company hardware

✓ 90%+ knowledge retention verified through practical assessments 3 months later

✓ Hands-on lab sessions with company’s actual equipment

✓ Ongoing support including alumni Slack channel and monthly follow-up sessions

Results: ✓ 8 out of 12 engineers now actively contributing to embedded projects

✓ Reduced dependency on external embedded contractors by 40%

✓ Faster product iterations due to improved cross-functional understanding

✓ ROI achieved in 6 months through reduced contractor costs (€120K saved)

✓ Team confidence increased significantly (measured via surveys)

✓ 2 engineers became internal embedded “champions” mentoring others

✓ Client requested advanced follow-up program for next year

Participant Feedback: “Before this training, I was intimidated by the code and avoided embedded discussions. Now I’m debugging CAN bus issues and even proposing firmware improvements. The hands-on approach using our actual products made all the difference.”

— Anders Svensson, Senior Mechanical Engineer

Client Testimonial: “Our mechanical engineers were intimidated by embedded systems before this training. Hisland’s approach – practical, relevant, and using our actual equipment – transformed them. Now they’re contributing to firmware discussions, identifying issues early, and we’ve significantly reduced our reliance on contractors. Best training investment we’ve made.”

— Erik Lindström, R&D Director, Manufacturing Equipment Supplier

Program Content: Embedded C programming, microcontroller architecture (ARM Cortex), sensor integration, CAN bus protocols, debugging techniques, RTOS basics, practical troubleshooting