You’ve designed the perfect thermal management system for an electric vehicle battery pack. The cooling channels are optimized for maximum heat transfer. The materials are selected for thermal conductivity and weight. The mechanical integration is elegant. But then the embedded systems engineer asks: “Where are the temperature sensor mounting points? What’s the thermal response time? How do we handle sensor failure modes?”

You realize your beautiful mechanical design is incomplete without considering the embedded electronics that will monitor, control, and protect it.

Welcome to modern mechanical engineering, where the distinction between mechanical and embedded systems has almost disappeared.

Why This Matters Now

Twenty years ago, mechanical and electrical engineering operated in relative isolation. Mechanical engineers designed physical systems; electrical engineers added sensors and controls afterward. This sequential approach worked for simpler products with limited electronic integration.

That world is gone.

Today’s reality:

- Electric vehicle powertrains are electromechanical systems where control algorithms determine mechanical performance

- Industrial robots require sub-millisecond coordination between mechanics, sensors, and actuators

- Autonomous vehicles depend on sensor fusion, where mechanical sensor placement directly impacts algorithm reliability

- Energy systems (heat pumps, battery storage) are optimized in real-time by embedded controllers

- Smart manufacturing equipment adapts mechanical behavior based on process feedback

The implication: Mechanical engineers who don’t understand embedded systems are designing for yesterday’s products.

This doesn’t mean mechanical engineers need to become software developers (though some cross-training helps). It means understanding enough about embedded systems to:

- Design mechanical components that integrate cleanly with sensors and actuators

- Communicate effectively with embedded systems engineers

- Make informed trade-offs between mechanical and electronic solutions

- Debug problems at the mechanical-electronic interface

- Recognize when embedded capabilities enable superior mechanical solutions

What Are Embedded Systems, Really?

Let’s demystify the terminology.

An embedded system is a computer system designed for a specific task, integrated into a larger mechanical or electronic product.

Unlike general-purpose computers, embedded systems:

- Have dedicated functions (control a motor, monitor temperature, manage battery charging)

- Operate in real-time with strict timing constraints

- Often have limited computing resources

- Run continuously, often for years without reboots

- Interact directly with physical world through sensors and actuators

- Must be extremely reliable (failure could damage equipment or endanger people)

Key components:

Microcontroller (MCU): The “brain”—a small computer chip executing control logic. Think of it as a highly specialized, real-time computer dedicated to controlling your mechanical system.

Sensors: Convert physical phenomena (temperature, pressure, position, vibration, current) into electrical signals the microcontroller can read.

Actuators: Convert electrical signals into physical action (motors, solenoids, valves, heaters).

Communication interfaces: How the embedded system talks to other systems (CAN bus in vehicles, Ethernet in industrial equipment, wireless protocols for IoT).

Power management: Ensuring reliable, clean power for electronics despite harsh mechanical environments.

Software: The algorithms running on the microcontroller—often more complex than you’d expect.

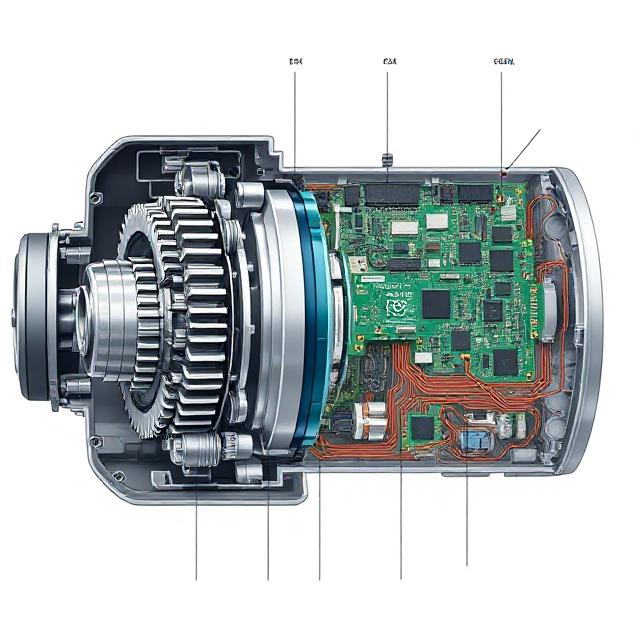

Example: Battery Management System (BMS)

Consider a lithium-ion battery pack in an EV:

Mechanical challenges:

- Structural integrity under vibration and crash loads

- Thermal management to keep cells in optimal temperature range

- Electrical connections handling high currents

- Manufacturing assembly and serviceability

Embedded system challenges:

- Monitor voltage and temperature of hundreds of individual cells

- Calculate state-of-charge and state-of-health

- Balance cells to prevent overcharge/undercharge

- Detect faults and initiate protective actions

- Communicate with vehicle control systems

- Optimize charging to extend battery life

The integration point: The mechanical design isn’t separate from embedded design—they’re inseparable. Sensor placement affects thermal response time, which affects control algorithm performance. Connector design affects signal integrity. Vibration isolation affects sensor accuracy. Cell balancing wiring becomes mechanical packaging constraint.

A mechanical engineer who designs the pack without understanding BMS requirements will create a system that’s difficult or impossible to control reliably.

The Fundamental Concepts

You don’t need a computer science degree, but you do need to understand certain embedded systems concepts to design effective mechatronic products.

1. Real-Time Constraints

Embedded systems often must respond within strict time windows.

Example: A motor controller for an electric power steering system must process sensor inputs and adjust motor torque within 1 millisecond. Miss that deadline, and steering becomes jerky or unresponsive—potentially dangerous.

Mechanical implications:

- Sensor placement affects signal propagation time

- Mechanical dynamics (natural frequencies, damping) must align with control update rates

- Physical constraints (actuator response time) set minimum control cycle times

- Testing must verify real-time performance under worst-case conditions

What you need to know: When you’re defining sensor locations or actuator specifications, ask: “What’s the required response time?” If the embedded team needs 100 Hz control (10 ms cycles), your mechanical components must respond faster than that—ideally 2-3x faster to avoid becoming the bottleneck.

2. Signal Integrity

Electronic signals are fragile. Physical factors you control as a mechanical engineer directly impact whether electronics work reliably.

Common signal integrity problems caused by mechanical design:

Electromagnetic Interference (EMI): High-current mechanical components (motors, solenoids) generate electromagnetic fields that interfere with sensor signals.

Mechanical solution: Shielding, grounding, separating high-power and low-power wiring, using twisted pairs for differential signals.

Vibration: Connectors can loosen, solder joints can crack, sensors can give false readings if mechanically excited at resonant frequencies.

Mechanical solution: Proper mounting, vibration isolation, connector selection with mechanical retention, avoiding resonant mounting.

Temperature extremes: Electronics have operating ranges. Your mechanical design determines whether those ranges are exceeded.

Mechanical solution: Thermal management (heat sinking, airflow, thermal barriers), component placement considering thermal gradients.

Moisture and contamination: Conformal coating and sealed enclosures protect electronics, but mechanical design determines ingress routes.

Mechanical solution: IP-rated enclosures, gaskets, drainage paths, cable glands.

What you need to know: When designing mechanical housings for electronics, don’t just think “this box protects the PCB from impacts.” Think: “This housing manages EMI, thermal environment, vibration isolation, and contamination protection—all of which affect signal quality.”

3. Sensor Selection and Placement

Sensors are the interface between mechanical world and embedded systems. Their selection and placement is often a mechanical engineering responsibility—but requires understanding electronic constraints.

Temperature sensors:

Mechanical considerations: Thermal mass of sensor, contact resistance with measured surface, response time.

Embedded considerations: Accuracy range, calibration requirements, interface type (analog, digital, I2C, SPI), update rate.

Common mistake: Placing temperature sensor on outer surface when controller needs core temperature. The mechanical design created a measurement that doesn’t match what the embedded algorithm needs.

Position sensors:

Mechanical considerations: Mounting precision, alignment tolerance, environmental protection, mechanical interface (shaft coupling, brackets).

Embedded considerations: Resolution, absolute vs. incremental, communication protocol, update rate, sensor fusion requirements.

Common mistake: Selecting a sensor based on accuracy spec alone, without considering update rate. A highly accurate sensor updating at 10 Hz can’t support a control loop requiring 1 kHz.

Force/torque sensors:

Mechanical considerations: Load path, mechanical stiffness, overload protection, mounting preload.

Embedded considerations: Sensitivity, noise floor, bandwidth, signal conditioning requirements.

Common mistake: Placing force sensor in mechanically complex load path where measuring the desired force is confounded by other loads. The embedded system sees noise, not signal.

What you need to know: When specifying sensors, have a conversation with the embedded engineer about:

- Required measurement range and accuracy

- Update rate needed for control algorithm

- Environmental conditions (temperature, vibration, EMI)

- Mounting precision and alignment requirements

- Signal conditioning and processing requirements

- Failure modes and diagnostic capabilities

4. Actuator Dynamics

Actuators convert electrical signals to mechanical action. Their mechanical characteristics fundamentally constrain what embedded controllers can achieve.

DC motors: Fast response, good control, require position feedback for precise control.

Stepper motors: Open-loop positioning, can lose steps under high load, limited torque at high speed.

Servo motors: High precision, closed-loop control, expensive.

Solenoids: Simple on/off actuation, force-displacement tradeoff, coil heating limits duty cycle.

Hydraulic actuators: High force, slow response, complex control, difficult to model precisely.

What you need to know: The embedded controller can only control what your mechanical system allows. If you specify an actuator with 50 ms response time, no amount of clever software can make the system respond in 10 ms.

When selecting actuators:

- Understand required bandwidth for the control task

- Communicate actuator dynamics (transfer functions, bandwidth, nonlinearities) to embedded engineers

- Don’t assume “more powerful is better”—oversized actuators can be harder to control precisely

- Consider whether closed-loop or open-loop control is needed

5. Control Algorithms and Mechanical Design

Modern embedded systems run sophisticated control algorithms: PID controllers, model predictive control, state estimators, sensor fusion. These algorithms make assumptions about mechanical system behavior.

Example: Electric motor control

A permanent magnet synchronous motor (PMSM) requires field-oriented control (FOC)—a sophisticated algorithm that treats the motor as a mathematical model to achieve precise torque control.

FOC assumptions:

- Rotor position known precisely in real-time

- Motor parameters (inductance, resistance) are accurate

- Current measurement is clean and fast

- Mechanical load is within model bounds

Mechanical design implications:

- Position sensor must be mechanically aligned with rotor within tight tolerance

- Motor windings should match specified parameters (manufacturing quality matters)

- Current sensors must be mounted to minimize noise pickup

- Mechanical load inertia and friction should be understood for tuning

Common mistake: Treating motor as “black box” that embedded team will “figure out with software.” Control quality depends critically on mechanical design quality.

What you need to know: Ask embedded engineers: “What assumptions does your control algorithm make about mechanical behavior?” Then design to meet those assumptions. If you can’t meet them, communicate that early so algorithms can be adapted.

Practical Skills: Bridging the Gap

Beyond conceptual understanding, certain practical skills help mechanical engineers work effectively with embedded systems.

Skill 1: Reading Schematics

You don’t need to design circuits, but being able to read an electrical schematic helps you understand:

- Where sensors get their power

- How signals route through the system

- Which components are critical vs. secondary

- Where failure modes might occur

- How your mechanical design affects signal paths

Start here: Learn to identify power, ground, sensors, microcontroller, communication buses. You don’t need to understand every component—just the system architecture.

Skill 2: Understanding Data Sheets

When specifying sensors or reviewing electronic component choices, you’ll encounter data sheets. Being able to extract key information is valuable.

Key parameters to understand:

- Operating voltage and current draw

- Temperature range

- Measurement range and accuracy

- Update rate / bandwidth

- Interface type (analog voltage, I2C, SPI, CAN)

- Mechanical mounting requirements

- Environmental ratings (IP rating, vibration tolerance)

Start here: Next time you specify a sensor, actually read its data sheet cover to cover. You’ll learn what matters and what’s marketing fluff.

Skill 3: Basic Debugging

When a mechatronic system doesn’t work, the problem is often at the mechanical-electronic interface. Basic debugging skills help you contribute to finding root cause.

Useful capabilities:

- Using a multimeter to verify sensor outputs are reasonable

- Checking connector integrity and wire continuity

- Recognizing when a “software problem” is actually a mechanical misalignment

- Documenting test conditions and system state when failures occur

Start here: Spend time with embedded engineers during integration and testing. Learn their debugging approaches. Offer mechanical insights when strange behavior might have mechanical root causes.

Skill 4: System Thinking

The most important skill isn’t technical—it’s the mindset of viewing mechanical and embedded systems as an integrated whole.

Poor approach: “I’ll design the mechanical system, then we’ll add sensors afterward.”

Better approach: “Let me understand what measurements and control actions are needed, then design mechanical system to enable them.”

Even better: “Let me explore whether embedded capabilities enable simpler mechanical solutions.”

Example: Traditional hydraulic systems use complex mechanical valve arrangements for control. Modern electric actuators with embedded control can achieve similar functionality with simpler mechanics but more sophisticated software. Recognizing this tradeoff space requires system-level thinking.

Real-World Applications

Let’s explore how these concepts apply in common mechanical engineering domains.

Automotive Powertrain

Traditional approach: Mechanical engineers designed engines, transmissions, drivelines. Electronics were limited to ignition timing and fuel injection.

Modern reality: Electric powertrains are fundamentally mechatronic. The “transmission” is often software-defined through motor control. Regenerative braking requires coordinating mechanical brakes, motor control, and battery management.

What mechanical engineers need to know:

- Motor control algorithms and their sensitivity to mechanical parameters

- Thermal management requirements driven by power electronics cooling needs

- Sensor requirements for torque vectoring and traction control

- NVH (noise, vibration, harshness) driven by PWM frequencies in motor control

- Mechanical isolation of power electronics from vibration

Industrial Robotics

Mechanical challenge: Design lightweight, stiff manipulators with minimal backlash for precise positioning.

Embedded challenge: Real-time motion control, trajectory planning, force control, sensor fusion for collision detection.

Integration challenges:

- Joint encoder placement and resolution determine positioning accuracy

- Mechanical compliance affects control stability and requires sophisticated compensation

- Cable routing affects signal integrity and mechanical life

- Force/torque sensors in joints require careful mechanical design to measure desired forces without crosstalk

What mechanical engineers need to know:

- How control algorithms handle mechanical backlash and compliance

- Timing requirements for motion control loops

- Force sensor calibration and zero-load conditions

- Mechanical resonances that control algorithms must avoid exciting

HVAC and Thermal Management

Mechanical challenge: Efficient heat exchange, fluid flow, compact packaging.

Embedded challenge: Optimize system efficiency in real-time based on external conditions, predict maintenance needs, balance comfort and energy cost.

Integration challenges:

- Variable-speed compressors and fans require motor control electronics

- Refrigerant sensors (pressure, temperature) drive control decisions

- Defrost cycles coordinated between mechanical valves and electronic control

- Grid integration for demand response requires communication capabilities

What mechanical engineers need to know:

- How embedded systems enable variable-speed operation for efficiency

- Sensor placement for accurate system state estimation

- Control strategies that optimize mechanical component life

- Grid communication requirements for smart HVAC

Medical Devices

Mechanical challenge: Biocompatible materials, precise fluid handling, compact packaging, sterilizability.

Embedded challenge: Real-time monitoring of patient state, closed-loop therapy delivery, safety interlocks, device connectivity.

Integration challenges:

- Sensors must survive sterilization without drift

- Actuators must provide precise, repeatable dosing

- Mechanical failures must be detected electronically

- User interface design spans mechanical and electronic

What mechanical engineers need to know:

- Medical device standards (IEC 60601) affecting design

- Software as a Medical Device (SaMD) regulations

- Failure mode analysis spanning mechanical and electronic

- Cybersecurity requirements for connected devices

The Learning Path

So you’re convinced you need to learn about embedded systems. Where do you start?

Level 1: Foundation (1-3 months)

Goal: Basic literacy to communicate with embedded engineers effectively.

Resources:

- Take an online course on embedded systems basics (Coursera, edX, YouTube)

- Read “Making Embedded Systems” by Elecia White (excellent introduction)

- Attend lunch-and-learn sessions with your embedded engineering colleagues

- Review schematics for products you’ve worked on mechanically

Hands-on project: Buy an Arduino or Raspberry Pi Pico. Build a simple temperature monitor that logs data. You’ll learn about microcontrollers, sensors, coding basics, and debugging.

Level 2: Applied Understanding (3-6 months)

Goal: Apply embedded concepts to improve your mechanical designs.

Actions:

- Participate in embedded system design reviews, asking questions

- Shadow an embedded engineer during integration and testing

- Take responsibility for sensor selection on a project (not just placement)

- Learn to read oscilloscope traces (understanding signal quality)

Hands-on project: Build a closed-loop motor controller. Control a DC motor’s speed using encoder feedback. You’ll learn about real-time control, PWM, sensor interfaces, and control algorithms.

Level 3: Integration Expertise (6-12 months)

Goal: Lead mechatronic system design, bridging mechanical and embedded effectively.

Actions:

- Propose projects where embedded capabilities enable better mechanical solutions

- Participate in system architecture decisions

- Develop test plans that verify mechanical-electronic integration

- Mentor other mechanical engineers on embedded basics

Hands-on project: Design a complete mechatronic subsystem (e.g., smart thermal management, automated positioning system). Own both mechanical and high-level embedded requirements.

Level 4: Specialization (Ongoing)

Goal: Deep expertise in your domain’s mechatronic challenges.

Actions:

- Formal training in control theory

- Certifications in relevant standards (automotive ASPICE, medical device development)

- Publish or present on mechatronic design approaches

- Contribute to cross-functional design tools and processes

Common Mistakes to Avoid

Learning from others’ mistakes is efficient:

Mistake 1: “We’ll add sensors later” Result: Mechanical design with no provision for sensor mounting, cable routing, or signal conditioning. Retrofit is expensive and often compromises performance.

Better approach: Include embedded systems engineer in conceptual design. Allocate space for sensors, connectors, and electronics from the start.

Mistake 2: “Software can compensate for that” Result: Mechanical problems (backlash, friction, resonances) that exceed what control algorithms can reasonably compensate for.

Better approach: Understand control algorithm limitations. Don’t assume software is magic that fixes mechanical issues.

Mistake 3: “This works on my desk” Result: System that functions in lab but fails in actual operating environment (temperature, vibration, EMI, contamination).

Better approach: Test under realistic conditions early. Design with generous margins for environmental factors.

Mistake 4: “The embedded team will figure it out” Result: Integration problems discovered late when changes are expensive.

Better approach: Collaborative design from day one. Regular integration checkpoints. Shared responsibility for system performance.

Mistake 5: “I don’t need to understand the code” Result: Inability to debug problems at mechanical-electronic interface. Miscommunication about requirements and constraints.

Better approach: Basic understanding of what the embedded code does (not necessarily how). Ask to see control logic. Understand sensor data flow.

The Future: Deepening Integration

The trend is clear: mechanical and embedded systems are merging into unified mechatronic systems. Future developments will deepen this integration:

AI/ML in embedded systems: Machine learning models running on microcontrollers enable adaptive control, predictive maintenance, and optimization impossible with traditional approaches.

Digital twins: Real-time embedded models of mechanical systems enable sophisticated diagnostics and control.

Connectivity: IoT and 5G mean embedded systems are networked, with new capabilities but also new vulnerabilities (cybersecurity).

Reconfigurability: Software-defined mechanical behavior—same hardware, different performance profiles via firmware.

Model-based design: Unified modeling environments where mechanical and embedded designs coexist, enabling co-simulation and optimization.

Mechanical engineers who embrace these trends will be invaluable. Those who resist will find their career options narrowing.

Conclusion: The Mechatronic Mindset

The message isn’t “mechanical engineers should become embedded engineers.” Both disciplines require deep expertise.

The message is: Modern mechanical engineering is inherently mechatronic.

You can’t design excellent mechanical systems in isolation from embedded systems anymore—not in automotive, not in industrial automation, not in energy systems, not in medical devices, not in consumer products.

The good news: you don’t need to become an expert in embedded systems. You need:

- Enough knowledge to ask good questions

- Enough understanding to make informed design decisions

- Enough fluency to communicate effectively with embedded colleagues

- Enough curiosity to keep learning as technology evolves

The mechanical engineers who thrive in the coming decades will be those who view embedded systems not as someone else’s problem, but as integral to creating exceptional mechanical solutions.

Start learning today. Your designs—and your career—will be better for it.

How Hisland Bridges Mechanical and Embedded Engineering

At Hisland, we don’t just write about the convergence of mechanical and embedded systems—we live it daily through our multidisciplinary Solution Providing approach.

The Challenge in Modern Product Development:

Most engineering firms operate in silos: mechanical engineers design hardware, electrical engineers add sensors and power, software engineers write control code. Integration happens late, problems are discovered late, and costly redesigns follow.

Hisland’s Integrated Approach:

Our Solution Providing model brings mechanical, electrical, software, and systems engineering under one roof—not as separate departments, but as integrated teams working collaboratively from concept through deployment.

What this means for mechatronic projects:

From Day One Integration: When you engage Hisland for a mechatronic solution (EV powertrain component, robotic system, smart HVAC, medical device), our team includes both mechanical and embedded systems expertise working together—not sequentially.

Comprehensive Solution Domains: Our work spans:

- Automotive & Electrification: Battery systems, power electronics, thermal management, motor control

- Energy & Smart Grids: Heat pumps, battery storage, smart controls, grid integration

- Manufacturing & Automation: Robotics, process control, sensor integration, IoT connectivity

- Smart Cities & IoT: Connected devices, sensor networks, edge computing

The Hislander Advantage: Our consultants aren’t just narrow specialists. Every Hislander completes Dynalope training developing:

- Systems thinking across disciplines

- Communication skills to bridge technical domains

- Cultural intelligence for global collaboration

- Proactive problem-solving at interfaces between disciplines

Real-World Application:

When we deploy a Hislander to your embedded systems project, they understand the mechanical constraints and opportunities. When we provide a mechanical engineering resource, they communicate effectively with your embedded team.

Our multidisciplinary capability means:

✓ Sensor placement decisions informed by both signal integrity and mechanical packaging constraints

✓ Thermal management designed for both mechanical efficiency and electronics reliability

✓ Control algorithms that respect mechanical system dynamics and limitations

✓ Mechanical designs that enable (not constrain) embedded system capabilities

✓ Early identification of integration challenges before they become expensive problems

Solution Providing, Not Just Staffing:

We don’t just place mechanical engineers on your team and wish you luck. We take ownership of complete functions:

- Requirements analysis spanning mechanical and electronic domains

- System architecture that optimizes the mechanical-embedded interface

- Integrated development with continuous validation

- Testing and validation across both domains

- Deployment with full documentation of interdependencies

Why This Matters for Your Projects:

Modern products fail most often at interfaces—between mechanical and embedded, between hardware and software, between design intent and manufacturing reality. Hisland’s integrated approach addresses these interfaces proactively, not reactively.

From concept to deployment, we handle the complexity of mechatronic integration so you can focus on your core business.

About the Author: This article is part of Hisland’s Eternal Evolution series, helping engineering professionals navigate the blurring boundaries between mechanical, electrical, and software engineering.

Need embedded systems expertise for your mechanical engineering challenges? Hisland’s multidisciplinary Solution Providing approach delivers complete mechatronic solutions—not just mechanical or embedded in isolation, but integrated systems that work.

Two ways to engage:

Solution Providing: Let us take ownership of a complete function or subsystem, handling all mechanical, electrical, and software aspects from requirements through deployment.

Hislander Consulting: Deploy our trained engineers to your team, bringing both technical expertise and the collaborative mindset needed for effective mechatronic development.

Ready to discuss your mechatronic challenges? Contact Hisland. We’ll help you understand whether you need solution providing, consulting resources, or something in between. Let’s build strength together through integrated engineering.